PREPARING THE LOT AND MELTING

In the section of the Automotive foundry are installed four medium frequency electric induction furnaces induction furnace that are used to melt solid metal cartridge. Installed furnaces from Junker manufacturers, two dual-track and four-pot for melting capacity od 4t.

Induction furnaces are simple generators to melt consisting mainly of refractory portion where melting, the induction coil that surrounds it and the supporting steel structure.

Due to the high frequency in these furnaces can melt and small metal cartridge. Also in the furnace is filled cold metal cartridge.

PREPARING THE SAND

Production process of mold mixture in the preparation of sand consists of the following operations:

- delivery and storage of new sand, bentonite, coal with pneumatic transport additives directly into the mixer

- extract the metal from the back sand with magnetic separators,

- isolation of the rest of the core on a polygonal screens polygonal screen

- new dosing and old sand, water and additives in mixers

- Mixing in MTI mixer 2500 (new mixer for new line), and optional mixer Speedmuller 100B.

- aeration and pre-mixing (loosening of sand)

- Transfer prepared mix to the place of molding

- testing of foundry sand and prepared mixes for molding, automatic control and correction of molding sand prepared for the new line, producers SPACE (ITA), Michenfelder (GER)

MOLDING

From the department of preparation of sand, prepared mixes for making molds are brought from

Conveyors into the hoper for molding a mixture set over Loramendi molding machines. From hoper mix is automatically dosed into the chamber, where is the compression of a mixture.

Machine molding provides consistent quality and greater dimensional accuracy of castings. Loramendi Vertical line is installed with PMC, SBC and drums for cooling castings. Dimensions of bentonite forms are 750x535x170 / 400.

Loramendi machine has an automatic investment core and foam filters in the form of bentonite.

CASTING

The molten metal, adjusted chemical composition, heated to the required temperature of the furnace ladle is transported to the casting machine. The molten metal is cast into the prepared form. Casting temperature depends on the quality of castings, ranging from 1350 to 1410 ° C.

Casting machine is siphon furnace performance to automatically casting of cast iron in fresh bentonite forms on auto-form Loramendi line 750 x 535.

The casting machine is designed so that the furnace under the pressure pour directly in the moving metal patterns.

Pourind slot FOMET is installed with automatic casting company Progelta with capacity of 10t.

CORE HOUSE

There are no currently installed capacity for the production of foundry cores.

FINISHING

Shootblasting

After mold outbreak or core dumping, castings go to blasting. With cleaning implies the removal of baked sand from the surface of castings. The process of cleaning the casting is done in a continuous flow-blasted with metal transporterom. The manufacturer Siapro blaster is installed with 8 Eco turbine blasting with the power of the 11kW. Flow blaster is such a capacity that can provide continuous blasting of castings with Loramendi lines.

In addition to the flow blasted that works in line (continuously) with the rest of the production equipment for the safety of the process at the department blasting are installed two drum blasted STEM 10 x 16 and 12.5 x 16. The restored blaster is put into operation with chain conveyor and four turbines.

Greanding

Foundry has a total of four machines for sanding:

- Two machines for automatic grinding type JUS Brno.

- Two hand-held bilateral grinders with grinding car Raichmann 600 / SK 600, ø 600 mm and four stationary grinder

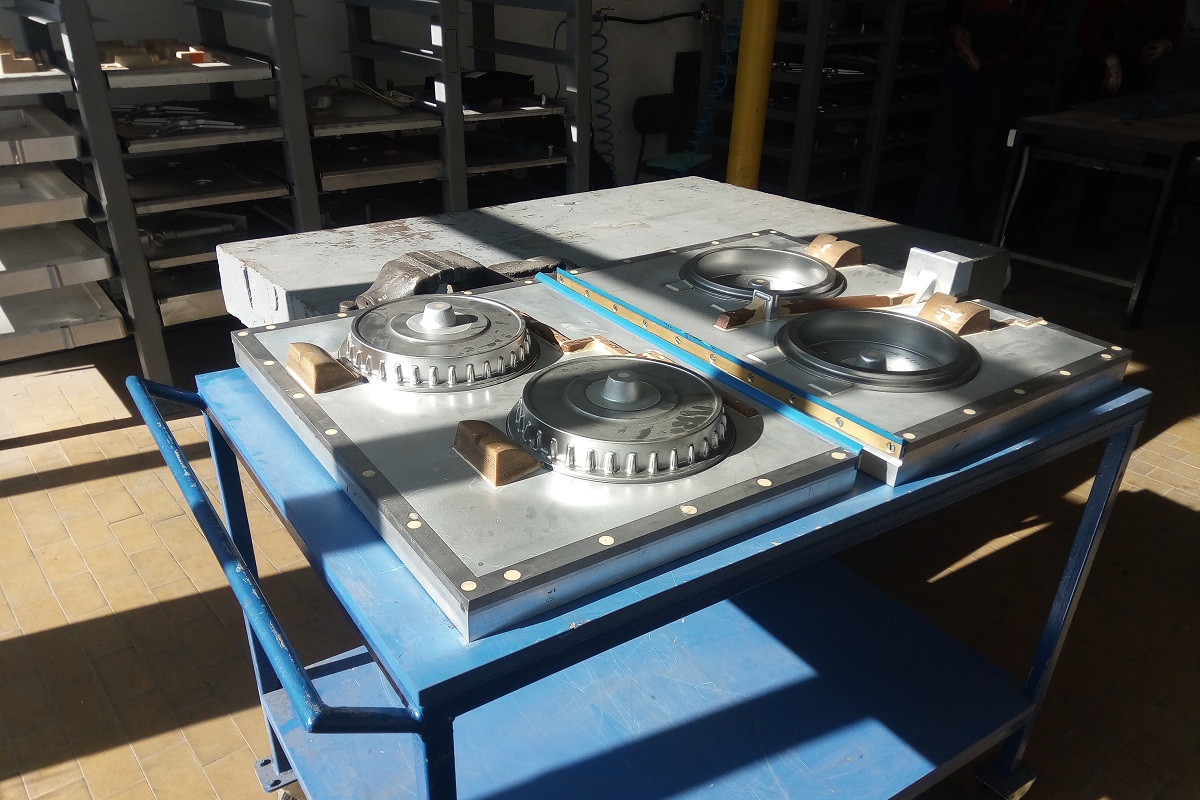

Automatic grinding castings

Automatic grinders are purpose-designed for grinding castings type brake drums, flywheels motor, brake discs. At the beginning of the grinding line manipulator to invest pieces on rolls. The rolls are driven by electric motor and their speed in relation to directly grinding cycle. Rolls of the castings are transported to the grinding wheel. For every position that sharpens the tools of making a reception where the cast is fixed during rotation. Thus, at the stage of grinding abrasive wheel is turning and standing vertically, and casting is horizontally fixed tool positioning and horizontally. Depending on the thickness burr grinding, adjusts the feed grinders and grinding cycle.

Hand sanding castings

Machines for hand sanding serve as a reserve variant automatic machines for grinding and as basic tools for grinding castings whose outer diameter exceeds fi. 260 mm. On these machines hand can do the finishing of castings.

Manual drilling castings

Four pole stable drills are installed for manual drilling of certain castings.

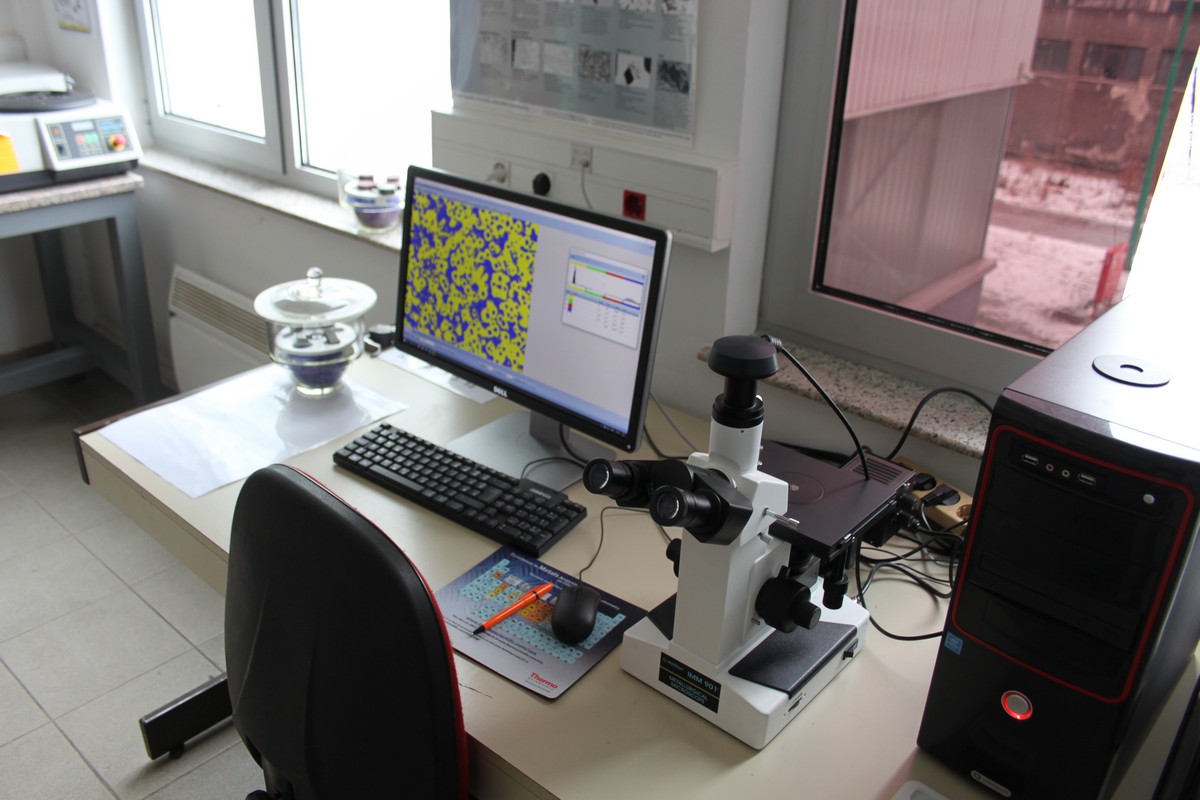

QUALITY CONTROL

Foundry Automotive has a laboratory for foundry sand, metallographic and laboratory testing of mechanical properties of metals. Within the foundry also has been installed the X-ray machine for internal quality control of castings.

Within laboratories were installed following devices:

- Spectrometer ARL manufacturer of cast iron, ductile iron

- Spectrometer ARL manufacturer of cast iron, ductile iron and steel castings

- Microscopes

- Laboratory equipment for testing the quality of sand manufacturers + GF + and Siapro

- Testing Machine

- hardness tester

- X-ray

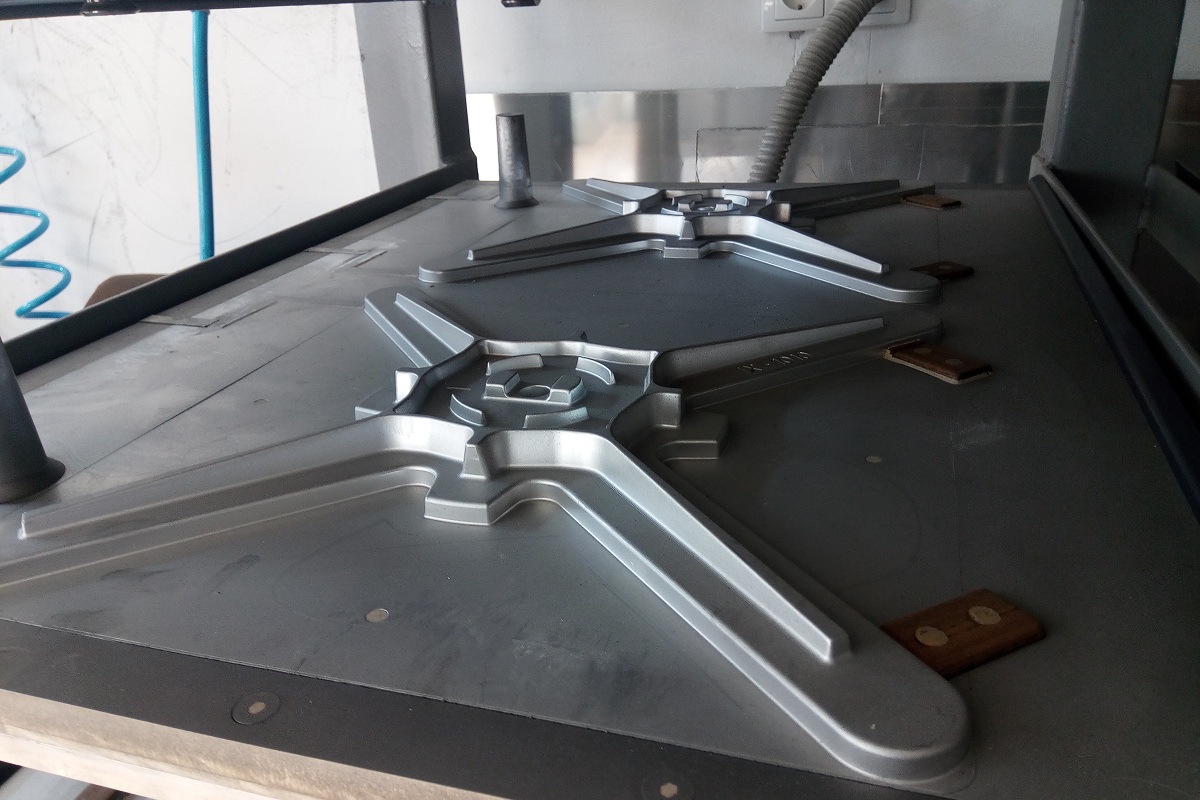

PATTERN SHOP

In this department foundry do the preparation, maintenance and modification tools for casting.