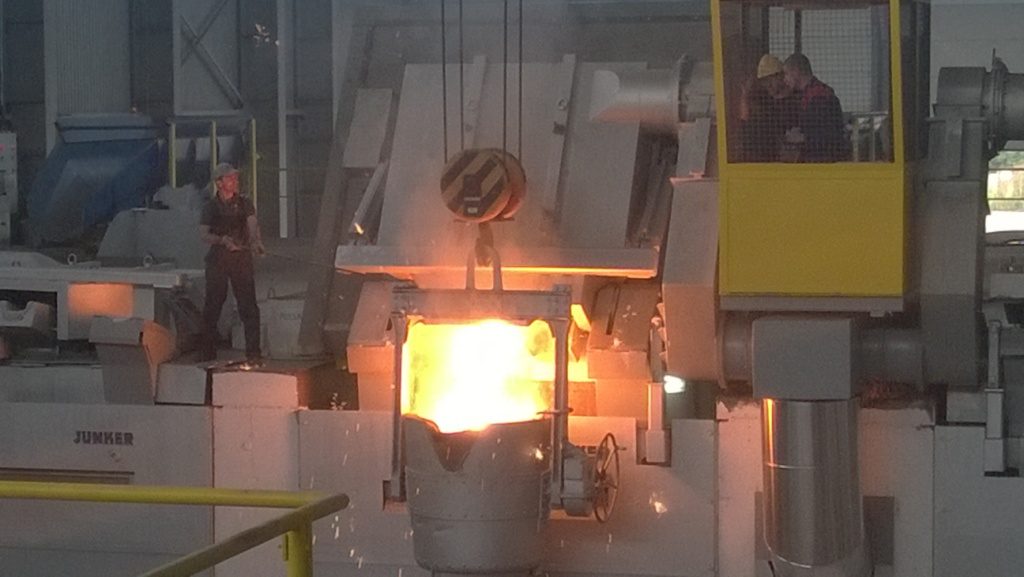

SMELTERY

We have two electric arc furnaces for melting metals with capacity of 15t. The cartridge melting consists of special raw steel material, worn rollers, steel scrap and ferro-alloys with familiar origin.

FINISHING / HEAT TREATMENT

The Department of thermal processing are two electric fry furnace with wagon capacity of 40 t, a device for improving the pits for cooling castings. Furnaces are equipped with controllers for automatic process control.

Finalization of castings is adapted dimensions of castings.

MOULDING AND CASTING

It is totally equipped with machines to produce rollers, molds, metallurgical, machine castings and other castings on request of customer. Sand molds for castings are hand made.

Drying the mold and heating the mold is carried out in dry kilns. Assembling the mold and casting is done in the pits of the properly dimensions. There are available cranes for transfering cargo carrying capacity 10, 20 and 40 t.

MACHINING

The operation processing machines, rollers turning dimensions of 1100 x 6000 mm and other heavy casts cast in the foundry large castings.

PATTERN SHOP

In this department of the foundry is making and modificating model devices for all castings according to wish of customer.

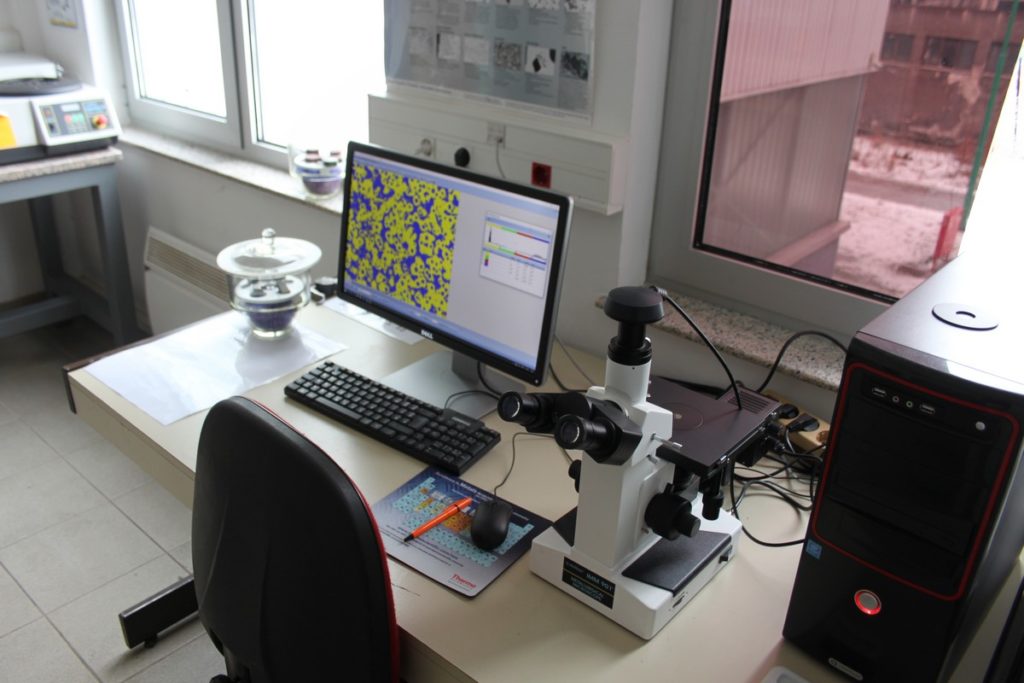

QUALITY CONTROL

For the purpose of quality control, chemical laboratory is equipped for the production of chemical analysis standard procedure and equipment for rapid analysis using an automatic spectrometer for steel, ductile iron and gray iron.